Time for a bit of an update on this. Unfortunately, I am

still chasing a clean, reliable rpm input to the ECU. I have given up on trying

to take the input from the coil packs, simply because I would like to have the

Microsquirt control ignition timing as well as fuel at some point so there is

no point going through the pain twice.

I have made some bit of progress though. First is the

trigger wheel definition. I made the fundamental mistake of not physically

looking at the wheel myself and relying on pictures from the manual. Of course

I didn’t realise that I was looking at pictures of a trigger wheel on an mc17

CBR250 which has the 8-1 trigger wheel. It was only after one of the members on

the cbr250.com forum questioned me on this that I realised that the mc22

trigger wheel was a 12-3 definition. That explained some of the erratic signals

and why the rpm was jumping to over 21,000rpm at idle. The ECU was expecting

teeth where there was none and gaps where there were teeth.

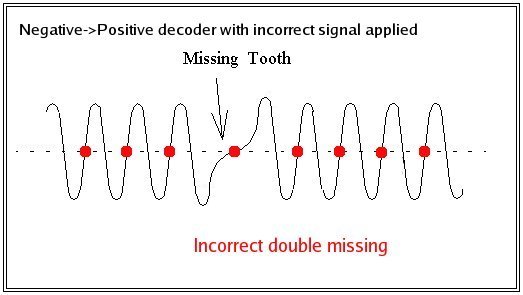

The problem is that this didn’t fix the issue… It did make

it better as in the signal peaks read by the ECU were consistent with the

actual running rpm of the engine but the signal was still constantly dropping

to zero. I tried a few combinations of noise filters within the Microsquirt

software but to no avail. After contacting DIYAutotune who I bought the

Microsquirt from, they have advised that I try switching to MSII/Extra firmware

as it includes some extra diagnostics tools to help isolate the issue. One of

these is the trigger tooth logger. I should be able to use this function to see

if the ECU is actually reading each trigger tooth correctly and thereby tell me

whether I need to concentrate on the VR signal coming into the ECU, or the

settings within the ECU.

I have an idea that if the signal entering the ECU is the

issue then I will attempt to convert the VR signal to a Hall signal externally

using an LM1815 chip and feed that into the ECU. The ECU should be able to read

the square wave Hall signal much more easily and cleanly than the AC VR signal.

Also, I have decided to go ahead and modify the GSR400

throttle bodies right away rather than attempt to tune the system on modified

carburettors and then do it all again with throttle bodies. I am currently

preparing the drawings for the throttle bodies, butterfly valve rods, fuel rail

and fuel rail mount adapters so that I can get quotes from a few machine shops

and get it kicked off. Once the throttle bodies are ready, that will be a major

part of the project complete.